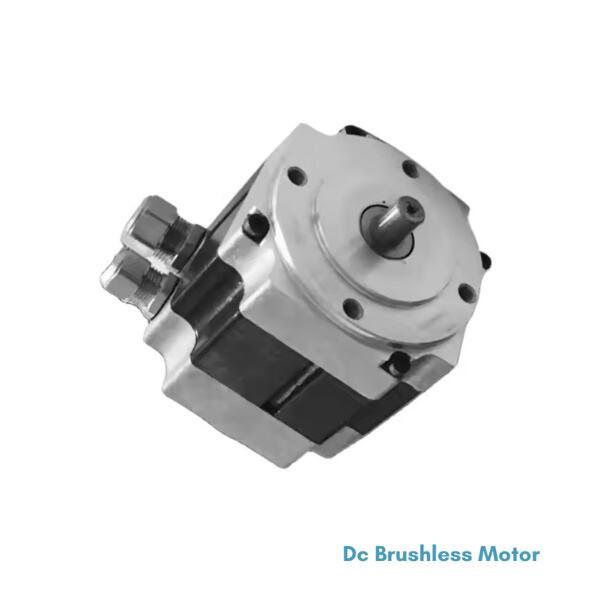

A motor is used in equipment to make it work, various machines used this technique today. The reason for this importance is that motors drive many devices around us. Brushless DC Electric Motor are one of the best motors presently we have. This motor has become a buzzword and is being used all over the industries as well as in homes. Why do people like it: It is very effective and reliable. One such company, McMaster Electric, has a reputation for producing quality DC Brushless Motorthat are preferred by many.

When speaking of motor types — brushless DC Motors have a wealth of advantages over other varieties. The main advantage is they are so durable and long-lasting. In other type of motors, we have brushes inside the motor (Brush Type Motors) but brushless DC Motor do not. They wear well over time because they lack brushes. Which also means that they need less grooming and care. This probably explains their popularity as they are meant to last.

Having said that, another benefit is for example Brushless DC Motors consume less electrical energy when compared with regular motors. That means they are extremely energy efficient and can save you money on your air conditioner bill. The McMaster Electric Brushless Motor also sound quieter when they run. It is ideal for homes and offices where silence matters. They also have exceptional speed control, and very easy to install. This means that they can deliver greater power and be implemented in a wide range of applications than conventional motors.

Due to its simple design, it is easier to understand how the Brushless DC Electric Motor works. It consists of two major parts, stator and rotor. The stator is the stationary part while the rotor rotates around it. The stator contains magnets and wire coils wrapped around it. But the rotor also contains magnets. But the case is different in Brushless Motor, it has no continuously on magnet at rotor. The stator doesn't pull the rotor, but instead creates a magnetic field that pushes the rotor along.

Electricity passes through coils of wire in the stator, creating a magnetic field. This magnetic field then causes the magnets on the rotor to begin rotating as well. Like all other positioning closed-loop motors, Brushless DC Motors require sensors that detect the exact position of the rotor at all times. The reason for this is because that information tells the motor how to adjust the power to the coils. You also have a control system that ensures that the motor operates smoothly and a timing system to bring very closely in synchrony all of these together.

Brushless Direct Current (DC) Motors are highly versatile in nature meaning they can be used in various applications. They are dependable, and they can be seen across various industries. As you can see, this whole new kind of computation is used everywhere: from aerospace to medicine; from robots to autonomous cars. Their precise speed control is one of their biggest advantages. They are an excellent option for fast and precise robotic movement.

And since Brushless DC Motors require minimal maintenance they are accordingly a fairly efficient components. This is highly crucial for medical devices: as safety matters more than anything else. These motors are also used in electric vehicles (car, bike), drones and computer cooling products. Because they fit in a multitude of settings — indoors, outdoors — they are a solid solution for many use cases.